How Yard Layout Impacts Crane Selection & Cantilever Design

How Yard Layout Affects Crane Selection and Cantilever Design – Planning for Efficiency and Safety

Introduction

The layout of a yard plays a critical role in crane operations, yet it's often overlooked until problems arise. How you arrange storage areas, vehicle paths, and loading zones can directly affect how efficiently your cranes work. A poorly planned yard may force operators to take longer paths, increase lifting time, or even restrict the type of crane you can use. In the worst cases, it can create safety hazards that put personnel and equipment at risk.

When the yard isn't optimized, several issues can show up quickly:

- Safety risks: Limited clearance or crowded paths can lead to collisions, load swings, or tipping hazards.

- Operational delays: Cranes spend more time traveling between points instead of lifting, slowing down workflow.

- Wear and tear: Frequent stops, starts, and long travel distances increase mechanical stress on crane components, shortening service life.

- Higher costs: Inefficient layouts may force the purchase of higher-capacity or specialized cranes unnecessarily.

This article is designed to help crane buyers, yard planners, and plant managers understand how yard layout affects both crane selection and cantilever design. By planning with practical details in mind—like storage depth, material sizes, and travel paths—you can choose the right crane type, properly design cantilevers, and ensure smooth, safe, and efficient operations.

In short, getting the yard layout right is not just about space—it's about matching your crane to your yard, your materials, and your workflow. Later sections will break down exactly how to evaluate your yard and make informed decisions for the cranes and cantilevers that best suit your needs.

Understanding Yard Layout

A yard layout is more than just empty space and a few paths. It's the blueprint of how materials, equipment, and personnel move through a facility every day. When we talk about yard layout, we're looking at how storage areas are organized, how vehicles and cranes navigate, and how loading and unloading zones are positioned. Even small details like aisle width or stacking orientation can have a big impact on crane performance and operational efficiency.

In practical terms, a yard layout includes:

- Storage areas: Where materials like steel slabs, coils, or containers are kept, whether stacked high or spread out.

- Traffic flow: Paths for trucks, forklifts, and cranes, including one-way or two-way lanes.

- Loading and unloading zones: Designated spots for picking up or dropping off materials, often near workshops, docks, or shipping areas.

- Workspace dimensions: Clearances, turning radii, and overhead space that determine what kind of crane can operate safely.

A clear understanding of these elements sets the foundation for making the right choices in crane type, span, and cantilever design.

Key Yard Layout Factors

Several yard factors influence crane selection and cantilever design. Understanding these ensures safe, efficient operations with minimal wear.

Yard Dimensions and Available Space

The overall length, width, and height determine crane travel limits and maximum span coverage. Tight or irregular layouts may require specialized cantilever solutions.

- Maximum travel paths and spans depend on yard dimensions.

- Tight or oddly shaped layouts may require customized cantilever lengths or specialized crane configurations.

Storage Patterns

Material arrangement affects crane efficiency and reach. Different stacking methods create unique handling challenges.

- Linear stacking: Straight lines allow predictable and quick pick-up.

- Block stacking: Dense piles maximize space but may need longer travel or cantilever extensions.

- Random stacking: Flexible but unpredictable, requiring cranes with adaptable reach and adjustable trolleys.

Material Type and Size

Material characteristics determine trolley positioning, hook reach, and load balancing on cantilevers.

- Large, heavy, or long items require higher lifting capacities and extended cantilevers.

- Material dimensions dictate whether standard trolley placement is sufficient or adjustments are needed.

Traffic and Access Requirements

Cranes must operate without interfering with vehicles, forklifts, or personnel to maintain safety and efficiency.

- Ensure clear, unobstructed paths for all yard traffic.

- Position cranes so their movement doesn't block trucks, forklifts, or personnel.

Seasonal or Operational Constraints

Weather, indoor/outdoor conditions, and seasonal material handling patterns affect crane and cantilever design.

- Cantilever length and crane protection should match environmental conditions.

- Adjust crane operation parameters to account for seasonal changes in material handling or weather.

Impact of Yard Layout on Crane Selection

Your yard layout directly influences which crane type and configuration will work efficiently. Considering space, operational needs, and movement paths ensures safety and productivity.

Choosing the Right Crane Type

Your yard layout sets the boundaries for crane selection. Consider width, length, material type, and movement frequency.

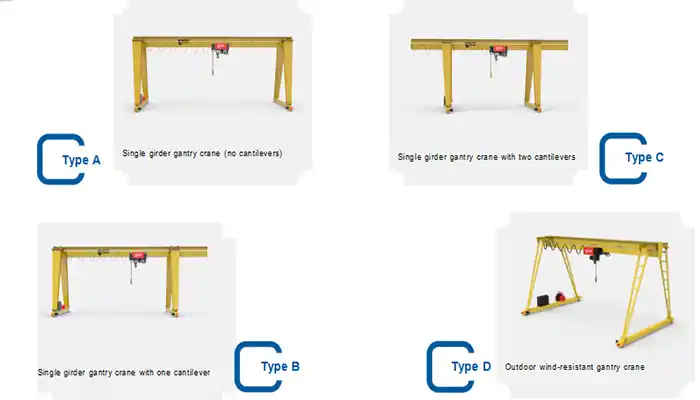

- Gantry Cranes (Single Girder Gantry Crane & Double Girder Gantry Crane, Full Gantry Crane and Semi Gantry ): Single girder for lighter loads/shorter spans; double girder for heavier loads/longer spans. Semi gantry cranes for indoor and outdoor use.

- Cantilever Gantry Cranes: Extend reach beyond the main span, ideal for offset loads or obstacles. Reduce manual repositioning for efficiency and safety.

- Mobile Rubber tyred Gantry or Rail-Mounted Cranes: Flexible in irregular layouts or temporary zones; serve multiple areas without permanent rails, though lifting capacity is lower than fixed gantry cranes.

- Always match crane type to yard space and material handling needs.

- Choosing the wrong type can reduce efficiency and increase risk.

Operational Requirements

Daily tasks determine crane specifications. Consider lift frequency, travel distance, and material stacking to prevent bottlenecks.

- Load Capacity vs. Block Size: Size cranes for the heaviest material, not the average. Include a safety margin.

- Span Requirements: Longer spans for wide aisles or dense stacking; adjustable trolleys or cantilever extensions for irregular materials.

- Lift Frequency and Cycle Time: High-frequency operations require faster trolley speeds and minimal idle time; low-frequency yards prioritize durability and simplicity.

- Evaluate your workflow before finalizing specifications.

- Factor in both maximum load and lifting frequency.

Space Constraints

Clearance, maneuverability, and travel paths are essential. Limited space can hinder crane performance and increase accident risk.

- Clearance Height: Ensure no interference with structures or machinery. Consider compact or under-running designs for low-clearance areas.

- Maneuverability in Tight Areas: Cantilever extensions can help reach hard-to-access spots safely.

- Multi-Directional Travel Needs: Decide if single trolley, double trolley, or adjustable cantilever is needed for lateral or diagonal movement.

- Plan crane travel paths alongside yard layout.

- Ensure enough space for safe operation while maintaining efficiency.

Cantilever gantry crane options: no cantilever, left cantilever, right cantilever, and double cantilever on both side of main girder

Cantilever Design and Yard Layout

Cantilevers extend crane reach, improve access to hard-to-reach loads, and must be carefully designed according to yard layout for safety and efficiency.

Purpose of Cantilevers

Cantilevers allow cranes to handle offset, irregular, or hard-to-access loads without additional travel or equipment.

- Extending reach beyond the main crane span: Access areas that would otherwise require repositioning or extra equipment.

- Improving access to irregularly shaped or offset loads: Safely lift materials not aligned with the main crane runway.

Design Factors Influenced by Layout

Yard layout affects cantilever length, load distribution, and integration with multiple cranes for safe and efficient operation.

- Cantilever length based on storage depth or stacking arrangement: Longer cantilevers may be needed for deeper or denser storage to prevent missed lifts.

- Load distribution and balance for safety: Even weight distribution prevents tipping, especially with heavy or off-center loads.

- Integration with multiple cranes in the same yard: Position cantilevers to avoid interference and collisions.

Safety Considerations

Proper cantilever design is critical to prevent tipping, maintain clearances, and control load swings in tight layouts.

- Preventing crane tipping or instability: Engineer cantilevers for maximum load capacity while maintaining balance.

- Clearance from obstacles, vehicles, and personnel: Ensure safe space for operation in congested yards.

- Load swing management in tight layouts: Plan cantilever and trolley movement to minimize swinging near other equipment or storage areas.

Efficiency Considerations

Optimizing crane efficiency involves minimizing travel, arranging materials smartly, and aligning operational flow to ensure smooth and productive yard operations.

Optimizing Travel Paths

Crane efficiency isn't just about lifting capacity—it's also about minimizing unnecessary movement between loads. Thoughtful planning ensures each lift is direct and productive.

- Reducing idle crane travel: Design the yard so cranes move the shortest distance between pick-up and drop-off points. Fewer idle trips save time and reduce mechanical stress.

- Minimizing overlap or interference between multiple cranes: When more than one crane operates in the same yard, plan travel paths carefully to avoid collisions and operational delays.

Stacking and Storage Strategy

How materials are stored directly affects crane performance. Proper stacking and placement reduce unnecessary repositioning and make the crane's work smoother and safer.

- Arranging materials for minimal repositioning: Place high-use or heavy items in accessible locations to limit repeated movements.

- Aligning crane reach with the most frequently moved loads: Frequently lifted materials should be positioned where the crane can reach easily without extending cantilevers excessively or changing trolleys.

Operational Flow

The overall flow of operations in the yard determines how efficiently cranes can operate. Aligning crane activity with traffic patterns, delivery schedules, and storage locations ensures smoother, faster handling of materials.

- Aligning crane travel direction with inbound/outbound material flow: Plan crane movement to match the natural direction of material movement, reducing stops and cross-traffic.

- Planning pick-up and drop-off points to avoid congestion: Designate clear zones for loading and unloading to prevent bottlenecks and keep cranes moving efficiently.

Case for Your Reference

Sometimes it's easier to understand crane selection and cantilever design when you see real-world scenarios. The following examples illustrate how different yard layouts influence the type of crane, cantilever design, and overall efficiency.

Compact Yard with High Stacking

In a small yard where materials are stacked densely, space is limited for crane travel. In this scenario, a double girder gantry crane with a short cantilever is often the most practical solution. The double girder provides the capacity needed for heavy loads, while the short cantilever allows access to the top and sides of stacked materials without taking up extra yard space.

- Optimizes lifting in tight areas.

- Reduces the need to reposition materials frequently.

- Maintains safe operation even with high stacks.

Wide Outdoor Yard

For a wide, open outdoor yard with offset loading and unloading zones, a cantilever gantry crane is ideal. The cantilever extends the reach beyond the main span, allowing operators to pick up materials positioned away from the main travel path. This design reduces downtime caused by repositioning and keeps workflow smooth in a large space.

- Extends reach to offset loads.

- Minimizes travel time across a wide yard.

- Provides flexibility for outdoor storage arrangements.

Mixed Storage (Slabs and Coils)

Yards that handle mixed material types, like slabs and coils, require adaptable solutions. A hybrid crane with an adjustable cantilever can handle different load sizes and shapes without constantly reconfiguring the setup. Adjustable cantilevers allow operators to move between slab stacks and coil piles efficiently while keeping safety margins intact.

- Adapts to varying material sizes and weights.

- Reduces crane downtime from reconfiguration.

- Ensures balanced load handling for safety and efficiency.

Practical Tips for Buyers and Planners

Planning a yard and selecting the right crane system can be complex, but a few practical steps can make the process much smoother. Involving the right people, thinking ahead for future needs, and considering safety and maintenance from the start will save time, reduce costs, and prevent operational headaches.

Involve Crane Suppliers Early in Yard Layout Design

Crane manufacturers and suppliers have hands-on experience with operational challenges that planners may not foresee. Engaging them during the layout design phase ensures that your crane paths, spans, and cantilever lengths are practical and match the real needs of your yard.

- Avoids last-minute adjustments or redesigns.

- Ensures the selected crane can handle all planned operations efficiently.

Consider Modular or Adjustable Cantilevers for Future Expansion

Yards often change over time, with new materials, storage patterns, or production requirements. Modular or adjustable cantilevers provide flexibility for future expansion without major equipment upgrades.

- Adapts to changing material sizes and layouts.

- Reduces costs when yard operations expand or shift.

Conduct Load Simulations for Safety and Efficiency

Simulating crane operations with actual load weights and travel paths helps identify potential safety hazards and efficiency bottlenecks before installation. These simulations can prevent accidents, reduce downtime, and improve workflow planning.

- Tests load distribution and cantilever limits safely.

- Helps optimize travel paths and lifting sequences.

Keep Maintenance and Inspection Access in Mind

Even the best crane design can underperform if maintenance is difficult. Plan crane positions, cantilever clearance, and aisle spacing so that technicians can access critical components without disrupting operations.

- Ensures safe, routine inspections.

- Reduces downtime and prolongs crane lifespan.

Conclusion

The layout of your yard is more than just a backdrop for operations—it directly influences which crane types will work, how cantilevers are designed, and how efficiently your materials are handled. A thoughtful layout can prevent safety issues, reduce unnecessary travel and repositioning, and ensure that cranes operate smoothly every day.

- Yard layout impacts crane type and cantilever design: Consider space, storage patterns, and material size when choosing equipment.

- Proper planning enhances safety and efficiency: Well-planned travel paths, stacking arrangements, and cantilever lengths minimize accidents and operational delays.

- Collaboration is key: Buyers should work closely with crane manufacturers and engineers to design solutions tailored to the yard's specific requirements, current operations, and future growth.

In the end, investing time in yard layout planning and crane selection pays off with smoother operations, safer working conditions, and longer-lasting equipment.